source:Industry News release time:2020-10-19 Article author:sznbone Popular:POGO PIN

Manufacturing process of different types of spring signal needle shaft!Spring signal pin connector is one of the connectors, which mainly plays a role of connection. The spring signal pin connector can be formulated according to the actual work requirements, and different specifications can be selected in the formulation. Today, we will follow the small series of Wanchang to understand the production process of different types of spring signal pin shaft.

1、 Flat head spring signal needle shaft:

1. Spring signal needle shaft flat head features: easy process, low cost;

2. Processing and manufacturing process: turning, vibration grinding process (removing burr, acute angle), electroplating process;

3. The main purpose of vibration grinding process is to remove the burr and sharp angle generated during processing, so as to avoid the situation of sand chuck during compression.

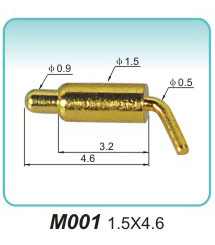

2、 Bevel side type spring signal needle shaft:

1. Spring signal needle shaft bevel features: are now commonly used specifications, electrical characteristics are very good;

2. Processing and manufacturing process: turning, secondary processing of beveled edge, vibration grinding process (removing burr, acute angle), electroplating process;

3. The main purpose of vibration grinding process is to remove the burr and sharp angle generated during processing, so as to avoid the situation of sand chuck during compression;

4. At present, there are two kinds of slope angles in the factory

1) 12 ° is convenient for the pre placement of the clock shaft. The required needle holder length is short and space saving.

2) 18 ° is now commonly used in the factory. The needle holder length required is long, and the fitting degree with the pipe wall is high after assembly, and the resistance value is good.

3、 Reverse drilling type spring signal needle shaft:

1. Spring signal needle shaft reverse drilling features: suitable for early compression stroke products;

2. Processing and manufacturing process: turning, secondary processing reverse drilling, vibration grinding process (removing burr, acute angle), electroplating process;

3. The main purpose of vibration grinding process is to remove the burr and sharp angle generated during processing, so as to avoid the situation of sand chuck during compression;

4. At present, there are two kinds of reverse drilling bit angles in the factory

1) 120 ° is convenient for drilling.

2) 160 ° is not conducive to drilling, but can increase the space for spring placement.

Shenzhen Witchip Electronics Co., Ltd. was established in 2004 and is located in Longgang District, Shenzhen. It has an independent factory building with an area of approximately 6,800 square meters. Integrating research and development, manufacturing, and sales, it is mainly engaged in the research and development and production of various POGOPIN and POGOPIN connectors, shrapnel terminals, and CNC automatic lathe parts. It can also be produced and processed according to customer samples. There are more than 4000 product categories for customers to choose. The products are widely used in various electronic products such as drones, smart robots, smart wearable products, 5G communication products, smart home products, education/entertainment electronics, medical equipment products, automotive electronics, mobile phone consumer electronics, etc.

The company’s R&D and designers are experienced engineering technicians with nearly 20 years of experience in the industry. The total number of employees is 120, with 80 CNC lathes, 100 automatic lathes, 80 assembly equipment, and projectors. Salt spray tester, life tester, current tester, high temperature tester, load dynamic impedance tester. In order to comply with the demand for market quality

The company passed the ISO9001 quality system certification in 2007 and successively passed the ISO14001 environmental system certification in 2009. It has 8 independent patents, which provide a solid guarantee for quality and delivery.

The company has always maintained a leading advantage in the field of Pogopin connector products, adhering to the business philosophy of "gratefulness, innovation, and creating value for customers", and has been recognized by some well-known companies at home and abroad, becoming their excellent connector supplier. Continuously win the trust of customers with quality and service, and establish a good reputation.

Read recommendations:

Problems that should be paid attention to in the selection of pogopin connector applications