source:Industry News release time:2021-03-09 Article author:sznbone Popular:POGO PIN

As we all know, gilding is a decorative technique and a common term. It originally referred to the plating of a thin layer of gold on the surface of the utensils. With the development, the use of gold plating on the surface of products has become more and more frequent, so what exactly is it?

Innovative development in the modern market, more frequent use of electroplated gold, electroplated gold can reduce contact resistance, make good electrical conductivity, products are easy to weld, strong corrosion resistance, and have a certain degree of wear resistance (referring to hard gold), so It is widely used in connectors, precision instruments, printed circuit boards, integrated circuits, etc., such as Pogo pin.

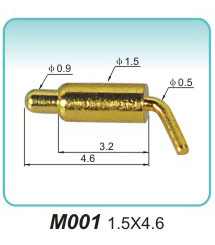

Pogo pin is a kind of Pogo pin that can be compressed and energized by the assembly, riveting and pre-compression of three basic components of needle shaft, spring and needle tube. It replaces various old versions of plug-in AC/DC power supplies on the market. , Micro USB, computer adapter, audio plug, RJ45, etc. Various functions, and can realize waterproof, safe, convenient and directionless charging (positive and negative charging).

Most of the current passes through the male and female butt, so that the Pogo pin is compressed to make it conductive. The elastic force, impedance and compression of the spring play a major role in the use of the product, such as the immature process or the friction and impedance of the internal structure of the spring. Large, making it difficult for the spring to compress normally, causing you to be busy in the end and realizing the function of the product.

Gold plating on the surface of pogo pin will directly affect the quality, reliability and appearance of a product.

For example, quality: Pogo pin is nickel-plated and gold-plated on the surface of the needle shaft, spring, needle tube and the inner wall of the parts! Then the Pogo pin can make the product safer in use, without long-term use of heat, deformation, burning, fire and other safety accidents, and it will not be difficult to achieve functions due to a small Pogopin and affect the entire product cannot be used.

For example, reliability: Pogo pin is nickel-plated at the bottom and gold-plated on the surface of the needle shaft, spring, needle tube and inner wall of the parts! Then the reliability of the Pogo pin will be better during use, such as current, elasticity, impedance, life, and oxidation resistance.

For example, beautiful: Pogo pin is gold-plated on the surface of the product. Assemble to a complete set of watches, bracelets, glasses, and other products. Because of the small size and the rich gold color, customers have a high-end, high-grade, low-key, luxurious and connotative product visual impact.

Read recommendations:

Spring contact pin M417 1.75x6.1

The function of measuring plate spring pogopin

The influence of different plating metal types on the surface of the pin jack of the car connector