source:pogo pin release time:2021-12-08 Article author:sznbone Popular:POGO PIN

During the test, the Pogo pin needle often comes into contact with the solder balls or pins, and the tin hanging condition inevitably occurs. The current method to solve this problem can be effectively controlled by changing the coating material of the needle.

Regarding the coating of Pogo pin needles, most of the materials currently used are Au materials. The adhesion of Au to Sn is relatively strong. In order to solve the problem of material characteristics, Pdco materials can be used instead of Au. Pdco is also the same. It is also a kind of precious metal. Compared with gold, it has the following material properties.

(1) Hardness

The hardness of Pdco is 450HV

The hardness of Au is 200HV

The surface hardness of Pdco is higher than that of Au, which makes Pdco have better wear resistance than Au

(2) Friction

The friction coefficient of Pdco is .40

The friction coefficient of Au is .65

The lower coefficient of friction can help the needle move more smoothly in the tube wall

(3) Particle size

The size of Pdco is 50-150 Angstroms

The particle size of Au is 200-250 Angstroms = 0.000000000001 m

Materials with small particles are more difficult to cause surface oxidation

(4) Toughness

Pdco: 3-7% elongation

Au: <3% elongation. Stronger surface toughness. Under the collision of the needle and the period of contact, the surface is less prone to cracks. From the above data, it can be seen that Pdco is superior to Au in terms of material properties. But all materials are not perfect. The most important aspect of resistance is that Au is higher than Pdco! (5) Resistance (data obtained by the same number of times under the same needle, different plating test environment) Au 19mΩ Pdco 26mΩ If you encounter products that are more sensitive to impedance data, the test yield of Au is lower than that of Pdco. In summary, aiming at the respective characteristics of Pdco and Au. KITA has developed a new coating alloy 2-2 that combines the characteristics of the two materials. In terms of electrical resistance, the data of alloy 2-2 is very close to the data of Au. At the same time, it can obtain the same characteristics of tin-free as Pdco, and both in terms of material hardness. It is higher than Au and Pdco. Comparison of hardness: Alloy 2-2 has a hardness of 680HV, Pdco has a hardness of 450HV, and Au has a hardness of 200HV. Alloy 2-2 is covered with 4 layers of gold on the basis of raw materials to achieve the required performance. Therefore, the new alloy 2-2 coating can be used to effectively improve the problem when the degree of tin hanging is relatively high. For more information about 2-2, please contact the sales department in China. Shenzhen Toplink Technology Co., Ltd. was established in 2005. We are a semiconductor testing company that provides Pogo pin in China. Welcome all the semiconductor testing brothers to discuss the problems encountered during the use of Pogo pin, and I am happy to serve you. There will be more Pogo pin basic technology introductions in the future!

Read recommendations:

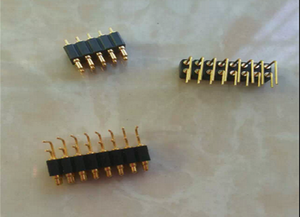

M3197 3.5X11.5(6A) E-cigarette pogo pin Manufacturing

Analyze the plating problem of the pogo pin magnetic connector

The pogopin connector makes the details meticulous.Magnetic Pogo Pin 16P