source:pogo pin release time:2022-03-25 Article author:sznbone Popular:POGO PIN

The electroplating process is a method of coating a conductor with a layer of metal using the principle of electrolysis. Electroplating refers to a surface processing method in which the base metal to be plated is used as the cathode in a salt solution containing pre-plated metal, and the cations of the pre-plated metal in the plating solution are deposited on the surface of the base metal through electrolysis to form a coating. .

The properties of the coating are different from those of the base metal and have new characteristics. According to the function of the coating, it is divided into protective coating, decorative coating and other functional coating.

During electroplating, the plated metal or other insoluble material is used as the anode, the workpiece to be plated is used as the cathode, and the cations of the plated metal are reduced on the surface of the workpiece to be plated to form a plated layer. It can enhance the corrosion resistance of metal (the coating metal is mostly corrosion-resistant metal), increase hardness, prevent wear, improve conductivity, smoothness, heat resistance and surface beauty.

Electroplating is an electrochemical process as well as a redox process. The basic process of electroplating is to immerse the part in a solution of metal salts as the cathode, and the metal plate as the anode. coating. For example, when nickel plating, the cathode is the part to be plated, and the anode is a pure nickel plate. The following reactions occur at the cathode and anode respectively:

Cathode (plated part): Ni2++2e→Ni (main reaction)

2H++2e→H2↑ (side reaction)

Anode (nickel plate): Ni-2e→Ni2+ (main reaction)

4OH--4e→2H2O+O2 (side reaction)

Not all metal ions can be deposited from the aqueous solution. If the side reaction of the reduction of hydrogen ions to hydrogen on the cathode is dominant, it is difficult for metal ions to precipitate on the cathode. According to experiments, the possibility of electrodeposition of metal ions from aqueous solutions , which can be obtained from the periodic table of elements.

Anodes are divided into soluble anodes and insoluble anodes. Most anodes are soluble anodes corresponding to the coating, such as zinc anodes for zinc plating, silver anodes for silver plating, and tin-lead alloy anodes for tin-lead alloy plating, but a few electroplating Due to the difficulty in dissolving the anode, insoluble anodes are used. For example, acid gold plating uses platinum or titanium anodes. The main salt ions of the plating solution are supplemented by adding a prepared standard gold-containing solution. The chromium plating anode uses pure lead and lead-tin alloy. Insoluble anodes such as lead-antimony alloys

Classification by coating composition:

(1) Chrome plating. Chromium is a silver-white metal with microstrip sky blue. Although the electrode potential is very negative, it has strong passivation properties, and it is quickly passivated in the atmosphere, showing the properties of precious metals, so the chrome plating layer of iron parts is a cathode plating layer. The chromium layer is very stable in the atmosphere and can maintain its luster for a long time. It is very stable in corrosive media such as alkali, nitric acid, sulfide, carbonate and organic acid, but it is soluble in hydrohalic acid such as hydrochloric acid and hot concentrated sulfuric acid. .

The chromium layer has high hardness, good wear resistance, strong reflective ability and good heat resistance. There is no obvious change in gloss and hardness below 500°C; when the temperature exceeds 500°C, it begins to oxidize and discolor; when it exceeds 700°C, it begins to soften. Due to the excellent performance of the chrome layer, it is widely used as the outer layer and functional coating of the protective-decorative coating system.

(2) Copper plating. The copper-plated layer is pink, soft, has good ductility, electrical and thermal conductivity, and is easy to polish. After proper chemical treatment, decorative colors such as bronze, copper green, black and natural color can be obtained. Copper plating is easy to lose its luster in the air, and when it reacts with carbon dioxide or chloride, a layer of basic copper carbonate or copper chloride film is formed on the surface, and brown or black copper sulfide is formed by the action of sulfide. Therefore, as a decorative The copper plating layer needs to be coated with an organic cover layer on the surface.

Read recommendations:

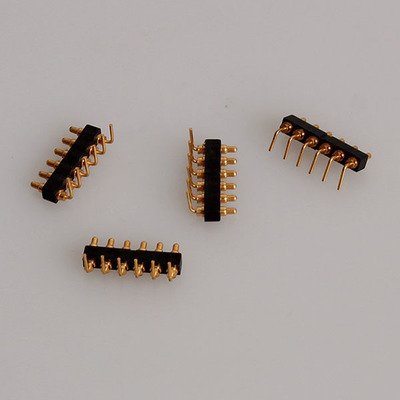

M1686 2.0X20(2A)Electronic connector price