source:pogo pin release time:2022-09-22 Article author:yu Popular:POGO PIN

As a precise hardware and electronic connection device, the spring thimble is used because of the particularity of its use. In order not to affect the use function of the product, the following points should be paid attention to when using it:

The first point: an important component of the spring thimble connector is the spring, and the spring has a certain range of compression/extension, so when choosing a spring thimble product, it is to consider the working stroke and compression of the environment in which it is used. In order to ensure the service life and stability of the pogo pin, it is recommended that the compression amount of the pogo pin is generally 2/3 of the total stroke during model selection; too little pressing and insufficient positive force will lead to unstable impedance; too much pressing, It will bruise the nozzle and cause the needle to stick. During the assembly process, care should also be taken to avoid bumping the nozzle, resulting in pin jams.

The second point: the contact direction, the contact direction when the spring thimble is applied directly affects the contact area and contact force of the contact of the spring thimble, and the size of the contact area and the contact force directly affects the size of the contact resistance, so in the design And the selection must initially pay attention to the contact direction.

The third point: The battery contact or FPC gold finger paired with the pogo pin must not be dirty, oxidized, etc. A: There should be no residual sealing liquid; the contact surface of the pogo pin should not be dirty, etc. B: There should be no other dirt residues? Avoid touching the plastic barrier during the assembly and use of the pogo pin.

The fourth point: the head of the spring thimble and the nozzle should avoid touching the plastic barrier during assembly and use. Avoid touching the plastic barrier during assembly and use of the pogo pin. The pogo pin seems to be a simple part, but if there is no one with good quality control and perfect manufacturing process level, it is very prone to power failure and stuck pogo pins, or durable Sex (life) is too short. The process is extremely delicate and complex. From lathe processing, electroplating, and assembly, each process may bring serious hidden dangers.

For example, lathe processing should be processed with Japanese automatic lathes. In this M, most factories use cutting machines for processing, and there is no way to guarantee the accuracy. Second, the surface finish of lathe processing, especially the inner surface finish of the needle tube is very critical. The vast majority of factories do not have surface roughness testing equipment and do not monitor this important parameter at all.

Read recommendations:

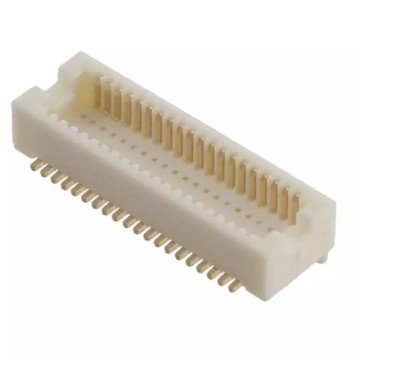

M3166 4.4X7.5(3A)Double-head Pogo Pin company