source:Industry News release time:2023-12-05 Article author:创始人 Popular:POGO PIN

For the testing of BTB/FPC mother connector, the vast majority of enterprises and manufacturers currently adopt a light touch solution to respond in a timely manner; When using a pogo pin manufacturer to test the mother socket, it can only contact the highest position of the connector terminal vertex. The contact area is small, and the contact method is point-to-point. The contact surface is relatively small compared to the spring contact surface, which is prone to wear and tear. After a certain number of uses, it is prone to poor contact, leading to errors in testing and other phenomena.

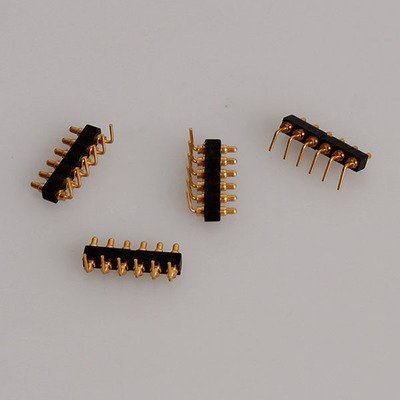

Pogopin probe module

Pogopin is a spring type probe formed by pre pressing the three basic components of spring, needle tube, and needle shaft; It is made up of several components, assembled, and coated, with complex process procedures, but its service life is still not high; Due to some issues with the pogopin itself, during actual testing of the BTB mother connector, we learned about the actual situation of some manufacturers:

1. The testing is unstable. The pogopin itself has a multi accessory structure and multiple contact points, which can easily lead to problems such as unstable contact and low impedance consistency;

2. During testing, the probe is often skewed, and personnel need to readjust the probe, which wastes a lot of time and labor costs;

Pogopin probe skewed, broken, or stuck

3. Card PIN: Also, due to the combination of multiple structures, this issue cannot be avoided in pogopins;

4. Extremely prone to needle breakage: As the pitch shrinks, the diameter of the pogo needle also decreases, increasing the risk of needle breakage for the probe;

5. Short service life: The probe has a service life of less than 30000 times and is prone to wear and tear. After using it for a certain period of time, it can easily lead to poor contact, false measurements, and other phenomena;

The above situations have a relatively high occurrence rate, which naturally leads to an increase in enterprise costs, poor testing stability, and low yield rates.

Read recommendations:

Design requirements for thimble connectors

Precision and stable pogopin connectors.2pin pogopin factory