source:Industry News release time:2024-03-11 Article author:创始人 Popular:POGO PIN

Probe type connectors, also known as pogo pin probe connectors, are mainly used in electronic products such as semiconductor devices to provide a certain degree of connection. As it belongs to a precision instrument, there are also some corresponding limitations in material selection. So, how should we choose better materials for pin connectors?

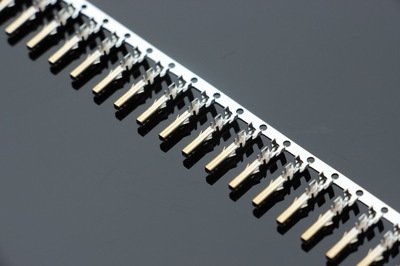

For probe type connectors, they are usually composed of three basic components: a needle, a spring, and a needle tube, mainly formed by riveting and preloading with some precision instruments to form spring type probes. For their needle materials, Becu or SK are often chosen. Of course, both types of materials have their own advantages and disadvantages. Generally speaking, Becu has better conductivity but lacks hardness, while SK has higher hardness and is prone to rusting.

In addition, the selection of spring material and needle material in pogopin connectors is different. Generally, spring materials include SUS SWP and PB free, and these materials must undergo corresponding tests before they can be truly put into use. The most commonly used type of needle material is PB material, which can easily lead to low yield. Generally, this is due to the wear of the needle, damage to the coating, and tin hanging on the needle during testing. These can even easily affect the service life of needles and springs, so in their selection and testing experiments, we should always pay attention and remain highly vigilant, in order to maximize their yield rate.

Read recommendations:

pogo pin for moilble phone M404 2x5.6pogo pin Manufacturing

Functional characteristics of magnetic connectors.spring loaded contact