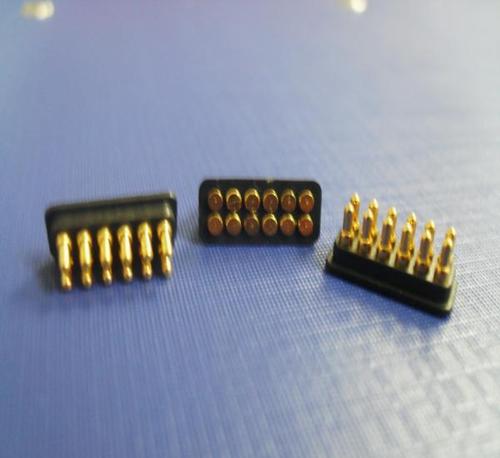

source:Industry News release time:2024-09-09 Article author:创始人 Popular:POGO PIN

The problem of poor fit between connector pins and crown springs may be caused by the following reasons:

1. Dimension mismatch: The dimensional tolerances of the pins and crown springs are unreasonable, resulting in the inability of the two to fit smoothly during assembly. This is usually due to lax dimensional control or inaccurate measurement during the manufacturing process.

2. Unqualified shape and position tolerances: The shape and position tolerances of the pins and crown springs do not meet the design requirements, such as the straightness of the pins and the concentricity of the crown springs, which will affect the smooth fit between the two.

3. Surface treatment problems: The surface treatment quality of the pins and crown springs is poor, such as rough surface, uneven plating, etc., which may cause jamming during assembly.

4. Improper assembly sequence and method: When assembling the connector, if the assembly sequence and method are incorrect, it may also cause the pins and crown springs to fit poorly. For example, excessive force or incorrect direction during assembly may cause damage or deformation of parts.

5. Parts quality issues: There are problems with the material and processing quality of the pin and crown spring, such as insufficient material strength, low processing accuracy, improper heat treatment, etc., which will affect the matching effect of the two.

Through the analysis and investigation of the above reasons, the specific problems that cause the connector pin and crown spring to match poorly can be found, and corresponding measures can be taken to improve them to ensure the assembly quality and performance of the connector.

Read recommendations:

Double-ended spring thimble M277 2X6.6pogo connector Vendor

Analyze the tolerance of round hole header!Negative contact pin Wholesale