source:Industry News release time:2024-09-29 Article author:创始人 Popular:POGO PIN

Pogopin, The choice of material for spring needles is crucial for their performance and reliability.

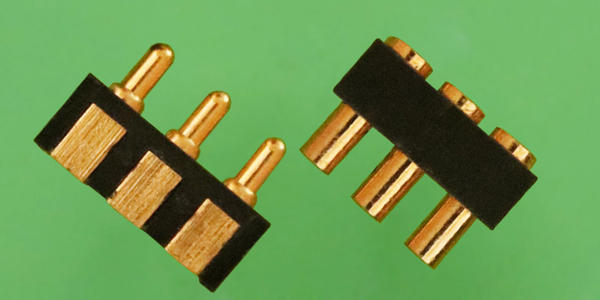

Generally speaking, the main components of Pogopin include the needle, spring, and syringe. Needles are usually made of brass or phosphor bronze. Brass has good conductivity and processability, ensuring stable current transmission. Phosphobronze has higher elasticity and corrosion resistance, making it suitable for some harsh environments.

Springs are mostly made of stainless steel material. Stainless steel springs have excellent elasticity and fatigue resistance, and can maintain stable contact pressure during long-term use. At the same time, stainless steel also has good corrosion resistance and can resist the influence of various environmental factors.

Needle tubes can be made of stainless steel, brass, or other alloy materials. Stainless steel needle tubes have high strength and good corrosion resistance, making them suitable for various application scenarios. Brass needle tubes have good conductivity and processability.

In addition, in order to improve the wear resistance and conductivity of Pogopin, some high-end products also undergo surface treatments such as gold plating and nickel plating. Gold plating can provide better conductivity and oxidation resistance, while nickel plating can enhance wear resistance and corrosion resistance.

Different material combinations can meet different application requirements. For example, in some situations where signal transmission is required, gold-plated brass needles, stainless steel springs, and needle tubes can be chosen; In some harsh environments, such as high temperature, high humidity, or corrosive environments, it may be necessary to use a combination of materials with higher corrosion resistance.

In short, the material selection of Pogopin needs to comprehensively consider factors such as conductivity, elasticity, corrosion resistance, and wear resistance to ensure that it can perform well in various application scenarios.

Read recommendations:

POGO PIN!pogo pin socket Vendor

Spring Pogopin stainless steel material penetration detection method

POGO PIN - The new darling of connectivity in the age of intelligence