Ordinary pogo pin is mainly composed of syringe, piston and spring. The

material of the piston head and the barrel is brass. Although it has good

conductivity, it has no elasticity. The spring material of stainless steel or

piano strings is characterized by poor conductivity and high resistance.

Generally, the current path of the ordinary pogo pin is through the friction

between the syringe and the piston to achieve current conduction, and the

friction between the syringe and the piston is related to the spring force. The

greater the elastic force, the greater the friction and the flow capacity. The

stronger. In addition, the impedance of the ordinary pogo pin is inversely

proportional to the elasticity, that is, the greater the elasticity, the greater

the friction, and the smaller the impedance, the more stable and reliable the

pogo pin, and the greater the resistance caused by friction, the greater the

resistance to the pogo pin The performance impact is also great, and its use on

the battery connector will cause the impedance to be too large and unstable,

instantaneously disconnected, and disconnected. Let’s take a look at the

difference between ordinary pogo pin and claw spring pogo pin with Tyco

Hanze.

The flow capacity of the aviation plug connector is mainly determined by

the diameter of the needle: the larger the diameter, the stronger the flow

capacity. The flow capacity of the claw spring pogo pin is also like this, the

current range through it is 2A~20A . Therefore, the claw spring pogo pin can

fully meet the current flow requirements of 5A~8A mobile phone battery

connectors. In terms of structure, the size of the claw spring pogo pin is

similar to that of the ordinary pogo pin, but the diameter of the claw spring

pogo pin exposed by the spring can be much smaller than that of the ordinary

pogo pin. Therefore, the size of the claw spring type pogo pin battery connector

can also be the same as the ordinary pogo pin battery connection machine, and

the claw spring type pogo pin with the spring exposed can be made into a thinner

battery connector.

Specifically, the difference between the claw spring type pogo pin

connector and the ordinary pogo pin connector is in the following aspects:

The high elastic claw spring of the former can ensure the reliability of

the connection under vibration and shock environment, and the hard connection of

the syringe and the piston in the latter has the risk of power failure in the

same situation.

The impedance of the former is stable and the resistance value is low,

while the impedance of the latter changes with the elastic force, and the

resistance value is relatively high; the direct friction between the piston and

the barrel of the former has nothing to do with the elastic force of the spring,

while the friction of the piston and the barrel of the latter is positively

related to the spring.

The oblique pressure of the former is absorbed by the plastic case when the

battery is installed, and has no effect on the pogo pin. The oblique pressure of

the latter is absorbed by the constriction of the syringe when the electric

hammer is installed, resulting in deformation and affecting the performance of

the pogo pin.

All strokes of the former are reliable working strokes, while only the

second half of the strokes of the latter are reliable.

Read recommendations:

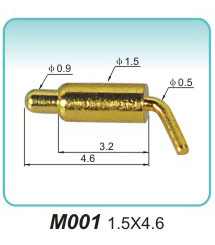

Signal contact pin

M1149 4.60x12.80(1A)

M2456 5.0x14(3A)magnetic pogo pin connector Vendor

Pogopin: Is it possible for the shield clip to replace the shield frame?Elastic contact factory

Introduction to the use of pogopin connectors