Pogo pin is a spring-type probe formed by the three basic components of

needle shaft, spring and needle tube after being riveted and preloaded by

precision instruments. There is a precision spring structure inside. The surface

coating of pogo pin is generally gold-plated, which can better improve its

anti-corrosion function, mechanical performance, electrical performance and so

on. The needle tip has a sharp needle, a grasping needle, a round needle, a

knife needle, etc.

Pogo pins are generally used for precision connections in electronic

products such as mobile phones, portable electronic devices, communications,

automobiles, medical treatment, and aerospace, which can improve the corrosion

resistance, stability, and durability of these connectors. Since the pogo pin is

a very fine probe, it can be used in a precision connector to reduce the weight

of the connector and the volume of the appearance, which can make the connector

more refined and beautiful.

Pogo pin needle tube, the needle is made by turning and milling one by one

copper rod; the traditional processing method is to use the tool feeder for

processing, and the processed product is not very accurate and low in cost;

Processing applications that do not require high accuracy of Pogo pin

products.

With the prevalence of smart phones and smart wearables, electronic

products are becoming more and more light, thin and compact, and the originally

limited space has become smaller; in order to meet the market demand, the size

of the Pogo pin connector is getting smaller and smaller. Pogo pin accuracy

requirements are getting higher and higher.

The accuracy of Pogo pin products processed by different processing

equipment will definitely be different, so what impact will the processing

accuracy have on the performance of Pogo pin products? Today we will discuss

this.

First of all, the surface finish of the high-precision Pogo pin product is

very high. The surface finish of the outer wall of the needle tube is not

particularly affected. The inner wall is the most affected. If the surface is

very rough, the friction coefficient of the Pogo pin will be when it is

elastically stretched. Very large, there may be stuck; the most important thing

is that the friction coefficient is too large when working, which will cause the

outer wall of the needle of the Pogo pin and the inner wall of the needle tube

to wear very seriously, thereby greatly shortening the service life of the Pogo

pin.

Secondly, the size error of the Pogo pin product is the product processed

with low-precision equipment, the size deviation will definitely be relatively

large, which will bring great trouble to the later assembly and application, and

the cooperation may not be ideal.

Read recommendations:

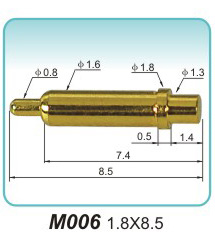

M2188 2.0x5.5(1A)Through Hole Pogo Pin Manufacturing

M2198 3.0x7.1(1A)

M1337 6.90x2.00(1A)

Why use pogo pin connectors!spring loaded pogo pins Direct sales

pogo pin phone connector.spring loaded pogo pins