source:pogo pin release time:2022-03-22 Article author:sznbone Popular:POGO PIN

1. The pogo pin connector requires high precision, which is easy to cause a high defect rate.

2. The contact point of the pogo pin connector will not move when it is compressed, and it is prone to connection failure when there is foreign matter or dirt in the contact position.

.Avoid stress from the side and other pogo pin connectors that are not vertical.

2. The battery contacts or FPC gold fingers paired with it must not be dirty, oxidized, etc.

3. Press too little and the positive force is not enough, which will cause the impedance to be unstable; press too much, the nozzle will be bruised, causing the pin to be stuck.

4. During the assembly process, care should be taken to avoid bumping the nozzle, which will cause the pin to be stuck.

5. The head and nozzle should avoid touching the plastic barrier during assembly and use.

Read recommendations:

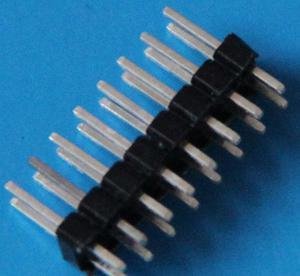

Double-ended spring thimble M277 2X6.6pogo connector Vendor

Pogopin: Customization of non-standard pogo pin connectors.Elastic contact factory