source:pogo pin release time:2022-05-11 Article author:yu Popular:POGO PIN

Due to the continuous increase of electronic control devices in modern automobiles, the number of connecting wires is inevitably increasing. In order to ensure the correctness and reliability of wire connections, wire connectors play a very important role.

The wire connector is a socket connected to the wiring harness. All sensor terminals use special interfaces. The connection between the control computer ECU and all external components is through the connector on the ECU, and the signal transfer in the wiring harness is also used. line connector. It can be considered that in an electronically controlled car, the control computer ECU is the control center, and the wiring harness is the neural network of the control system. Then, the wire connector is the relay station of the circuit wiring harness. However, in addition to the convenience of installation and accurate wiring, the connector often fails in use, and the most common failure is poor contact, which leads to the interruption of "network" signal transmission, which directly affects the good performance of electronically controlled vehicles. play normally.

Wire and connector open circuit

The wire and connector open circuit fault may be caused by the wire being broken during use, the connector being in poor contact, and the connector terminal being loose.

Since it is very rare for the wire to be disconnected in the middle, most of it is disconnected at the connector. Therefore, the inspection should focus on carefully checking the sensor and the wire where the connection is located, whether there is looseness and poor contact.

The open-circuit fault of the connector caused by poor contact is often caused by the corrosion of the connector end, and the external dirt entering the terminal or connecting socket, resulting in a decrease in contact pressure. At this time, as long as the connector is removed, and then re-inserted to change its connection status, it can return to normal contact.

Wire and connector short circuit fault

The failure of wires and connectors can also be caused by a short circuit between the harness and the body (ground) or within the relevant switch. Before checking, you should first check whether the wire connector on the body is firmly fixed, and then you can test according to the following steps.

(1) Check the continuity of the wire

First, remove the wire connectors on both sides of the control computer ECU and the sensor, and then measure the resistance between the corresponding terminals of the connector. If the resistance value is not more than 1 ohm, the wire is normal, so that the next step can be checked. When measuring wire resistance, it is best to shake the wire slightly in both vertical and horizontal directions to improve the accuracy of the measurement. The stem of the waterproof connector with the waterproof cover cannot be inserted from the rear, because the terminal can be deformed if inserted carelessly.

(2) Check the resistance value of the short circuit

First, remove the wire connectors on both sides of the control computer ECU and the sensor, and then measure the resistance between the terminals of the connectors on both sides and the body. When measuring, one end of the watch rod is grounded to the body, and the other end should be measured on the wire connectors on both sides respectively. If the resistance value is greater than 1 ohm, it means that the wire and the body have no short-circuit fault.

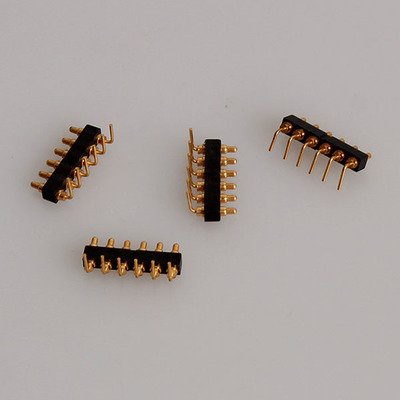

Connector appearance and contact pressure inspection

First, remove each wire connector one by one, check whether there is rust and dirt on the connector terminals, and clean up the rust and dirt. Then check whether the terminal piece is loose or damaged, whether the terminal is firmly fixed, and there should be no looseness when pulling gently. Conversely, if the plug terminal in one of the socket holes is easier to pull out than the other socket holes, the socket hole may cause a failure of poor contact in use.

Precautions when checking

(1) The inspection of the connector must be carried out with the ignition lock closed, otherwise the related parts will be burned out due to self-induction.

(2) When removing the wire connector, pay attention to loosening the locking spring or pressing the lock button, and do not pull it hard. When reassembling, insert the connector to the end and lock it.

Read recommendations:

M2585 2.2x23.17(1A)titanium electrode company

M1185 4.1x12.65(2A)nucleic acid probe manufacturer

Connector function and application!types of electrodes in electrochemistry

An effective means for pogo pin connector company to improve product quality.ground electrode Direct