source:pogo pin release time:2022-05-28 Article author:yu Popular:POGO PIN

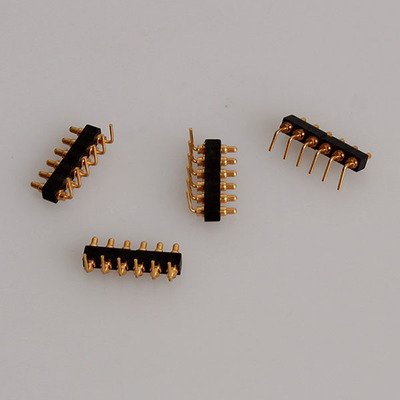

New custom waterproof spring connectors (pogo pins) provide advanced protection for portable devices in harsh environments. Pogo pins with press fit and O-ring assemblies achieve up to IPx7 water resistance while reducing the need for additional water resistance and protection in device docking stations and terminals.

Manual and wave soldering do not apply excessive heat to the case. Pogo pins. Terminals require insert molding. The basic specifications of the waterproof spring connector include a current rating of AC/DC 12V 2A, an operating temperature of -40oC - +85oC, and a rated endurance of 100K cycles. It is also possible to further customize spring loaded connector solutions to meet specific design requirements, environments and needs.

Applications for waterproof connectors include data collection terminals, data communication devices, wireless devices, mobile GPS devices, and any other type of device that docks within a charging station.

Now the commonly used connectors have a plating layer on the periphery. The thickness of the connector plating layer and the material of the connector plating layer are determined according to the use of the connector. Why do connectors generally need plating surface layers?

The electroplating layer on the surface of the connector can prevent the connector from being corroded by oxidation and vulcanization in the working environment, protect the connector and prolong the service life of the connector. The electroplating layer on the surface of the connector can improve the mechanical properties of the connector such as ductility, durability, wear resistance, and mating force. The electroplating layer on the surface of the connector can stabilize the impedance of the connector and make the electrical performance of the connector more stable. The electroplating layer on the surface of the connector can isolate harmful substances in the environment, which not only reduces the damage to the connector, but also increases the wear resistance of the connector.

The electroplating layer on the surface of the connector not only protects the connector, but also improves the working performance in some aspects. The electroplating layer is the protector of the normal use of the connector. Now some connector manufacturers are choosing more stable coating materials that can make the connector work.

Read recommendations:

M2638 1.36x5.3(1A)thimble company

connectors need to be plated.gene probe Processor

What are the design principles of radio frequency coaxial connectors