There are different appearances depending on the application, but as a

whole there is a precision spring structure inside the pogo pin. The surface of

the product is generally gold-plated, and the spring should also be gold-plated

when the process requires.

The thimble is energized or turned on, most of which are in contact with

the copper wall through the oblique downward direction, and the spring bears a

small amount, so the inner wall of the copper sleeve is required to be

smooth.

The electrical characteristics will actively find the path with the

smallest resistance value to conduct the current. If the POGOPIN factory makes a

non-beveled surface, but the bottom is flat, most of the current must be

conducted through the spring, and the requirements for the spring will be very

high.

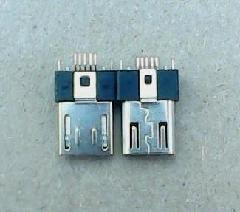

Pogo pin is a spring-type probe formed by riveting and pre-pressing the

three basic components of needle shaft, spring and needle tube through precision

instruments. There is a precise spring structure inside. The surface coating of

pogo pin is generally gold-plated, which can better improve its anti-corrosion

function, mechanical properties, electrical properties, etc. The needle tip has

a sharp needle, a grasping needle, a round needle, a knife needle, and the like.

Pogo pins are generally used in precision connections in electronic products

such as mobile phones, portable electronic equipment, communications,

automobiles, medical care, aerospace and other electronic products, which can

improve the corrosion resistance, stability and durability of these connectors.

Since the pogo pin is a very fine probe, it can be used in precision connectors

to reduce the weight of the connector and the volume of its appearance, which

can make the connector more fine and beautiful.

The amount of current carried by different structures is different, and

different structures can also be applied to different functional designs, and

the number of contact points will also affect the amount of current.

Read recommendations:

M1422 3.10x5.45(1A)

M820 0.8X7.3

M1193 1.50x13.30(1A)

Advantages of pogo pin!Solder-cup Pogo Pin price

How to judge the pogopin momentary interruption problem?